Hi all, several divers have asked me about my current buoyancy control device (BCD) configuration and I think it’s a good time to share a little more on how arrived at my current setup. After testing and researching half a dozen BCD manufacturers and their product solutions, I found that none of them really matched what I preferred as an off-the shelf solution, so I decided to assemble my own.

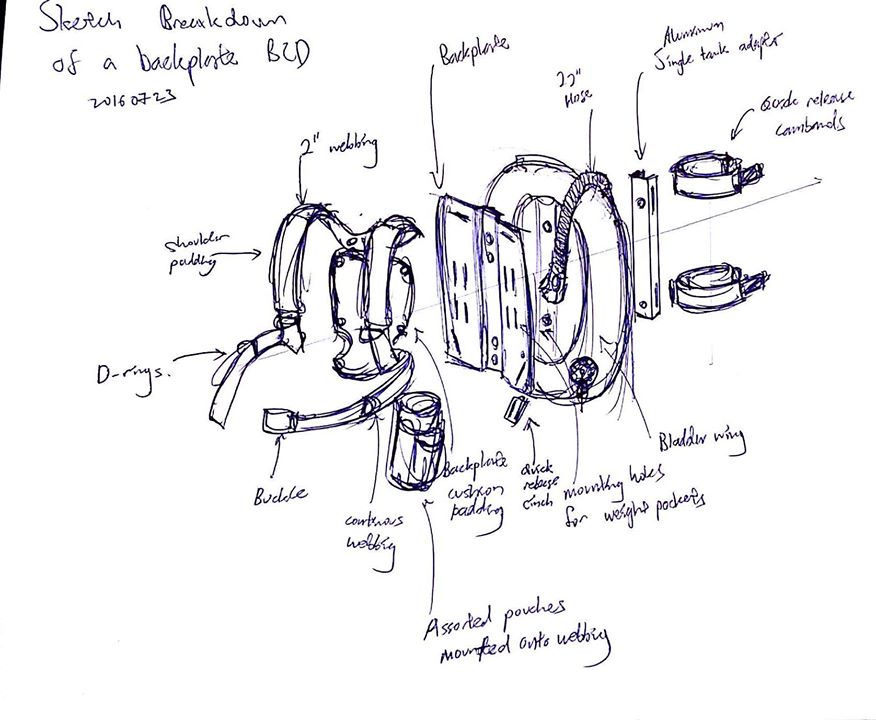

There are two main types of BCDs, a jacket and a backplate-wing. As a backplate, however typical backplate BCDs are made from stainless-steel for its rigidity and strength, the downside is that SS is heavy, and weight counts when travelling. With the addition for further gear and apparatus to my setup, I realized that it’s a challenge to keep the weight of the checked luggage below Airline recommended limits up to 32kg (depending on the airline you’re flying with). Not to mention hefting a 20-30kg odd piece of luggage/gear when moving from boat to boat is a recipe for a potential accident. That started the weight-loss pursuit for my bulky scuba gear. The criteria were simple: find or build a BCD that was light and yet technical-capable (pony/stage-tanks etc. That precluded most travel BCDs and typical stainless steel backplate BCDs weigh about 3kg, most of the weight comes from the stainless steel backplate. For inspiration, I looked at several load-bearing harness arrangements from the military MOLLE systems and came up with my own design.

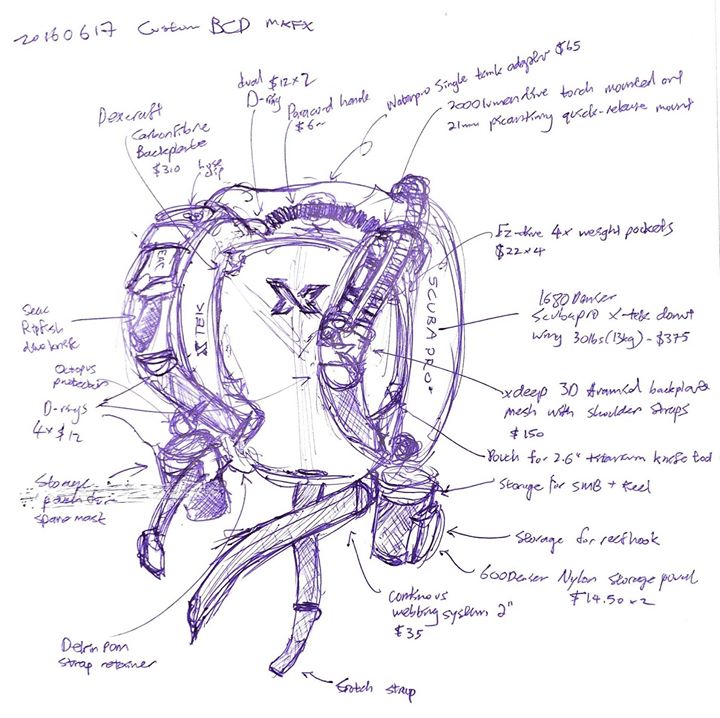

It would be simple, an assembly of existing parts from various scuba product providers and yet won’t deviate too unconventionally for a recognizable gear setup with minimal custom components.

Some features were mainly ergonomic for most efficient anatomical access to essential gear. On my right shoulder pad would be a quick release knife that I could release with my left hand singlehandedly where the thumb release faces my medial sagittal since my master hand is my left.

My SMB will be in a single nylon pouch that is accessible and deploy-able with one left hand on the left of the bcd (left facing forward, it is on the right in the sketch) maybe I should use marine terms ‘port’ and ‘starboard’.

My spare mask will be placed in another storage pouch on the right since I’d likely be using my right hand to replace a lost mask if my left hand is occupied with gear or lines. At the point of the sketch, I’ve yet to decide how to mount my dive torch to the BCD should webbing. I want it to be instantly available and lighted hands-free in the event I need to handle lines / stage-tanks in a murky/poorly-lit environment where I’d need a light yet need my hands-free to manage gear. However if I put my torch mounted on the left, that will interfere with my inflator hose. So likely I will do a quick-release mount on the left in favour over my knife.

The webbing will be the standard 2” continuous system and D-rings in strategic places for mounting/attaching gear and I’ve decided to add a nice handle at the top made from paracord for carrying /drying/ hanging the entire BCD. More details on the different component selected later.

The backplate is the main question. It’s the one major component that has to fat-trimmed. I had initially thought of getting Waterpro’s anodized aluminium backplate, but thought – why not go even lighter?

Waterpro’s anodized aluminium backplate seen at ADEX 2015Whilst aluminium is lighter, it is also mechanically weaker than stainless steel, to ensure that the tough demands of technical diving loads are met; I looked into something even stronger and lighter…

Carbon Fibre.

This is the stuff that makes Formula-1 and supercars that one can only dream of, and I was pleasantly surprised that I didn’t have to custom one as there were automobile-part manufacturers producing carbon-fibre components and body parts.

Dexcraft’s Ultra lightweight carbon fiber diving backplate weighs 400 grams with a tensile strength of 1760MPa (Mega-Pascals) and a cost $330 SGD, or €205.00, 6.75 items lighter than a steel one (2.7kg) and 2.25 times lighter than an aluminium backplate (0.9kg). The CF-backplate is made from a 4/4 unique weave. Carbon fiber reinforced polymer (CF) ensures strength a few times improved comparing to steel products of the same weight. Here’s a table of the equivalent strengths of the materials typically used to make BCD backplates:

| 316 stainless steel | 7000-Aluminium | Carbon Fibre | |

| Weight of backplate | 2,700g | 900g | 400g |

| Tensile strength | 620 MPa | 295 MPa | 1760 MPa |

| Fatigue strength (1M cycles) | 303 MPa | 83 MPa | 1510 MPa |

| Strength to weight ratio | 0.229 | 0.431 | 4.40 |

Did I mention the off the charts strength-to-weight ratio of 4.40?! That’s 19 times stronger than 316 marine-grade stainless steel. (Further information on 316-type steels, material comparison table here).

When comparing carbon fibre with other commonly used building materials. The strength and modulus (a measure of how much a material deforms under load) of carbon fibre is impressive. However it’s most important attribute is the combination of high specific strength, specific modulus and fatigue resistance. By dividing the strength and modulus values by the density, one is able to compare the weight of each material required to carry a load. A high fatigue resistance allows a structure to carry loads close to its stress limit, without the fear of unacceptably shortening its working life. Aluminium and stainless steel have poor fatigue properties.

The fatigue resistance of carbon fibre/epoxy resin composite material is far superior to both metals and other composites. It is relatively insensitive to fatigue damage even at very high stress levels. Carbon fibre, despite it’s high cost, is the ideal material, Its properties allow the BCD to be light, strong and durable. I won’t go into the specifics of metallurgy and material engineering so as not to make this entry too technical. It’s just that carbon fibre is currently the lightest and strongest material economically available that Elon musk is building his spacecraft fuel tanks with it.

I got myself a a carbon fibre backplate. It’s so pretty.

As for the bladders, the main consideration with the toughness of the outer cladding, it must be as tough as possible to resist abrasion and abuse from accidentally scraping past rocks or walls during a cave dive or against possible sharp edges in a wreck dive. Since most bladders have standard mounting rings, they will be compatible in a single-tank or twin-tank setup.

The uniformity of the donut is important for stability and balance – meaning no dead zones or air pocket traps, thus making diving trim easy and effortless. A dive trim must remain stable and with a consistently horizontal profile, regardless of the pressure in the cylinders or the amount of air in the bladder. With those considerations, the semi-finalists were a toss-up between the IST Dolphin JT-30D, Sopras Tek xTech Kevlar, Halcyon Infinity, xDeep hydros or the Scubapro x-tek donut wings. Since the weight for each of the bladders were within the ballpark of each other, the last variable consideration was cost:

| Bladder | Bladder material | Approx Cost |

| Scubapro x-tek 30lb | CORDURA® 1680 denier | ~$400 |

| IST Dolphin JT-30D | CORDURA® 1680 denier | ~$500 |

| xDeep hydros 40lbs | CORDURA® 1100 denier | ~$500 |

| Halycon Infinity 30lbs | CORDURA® 1000 denier | ~$650 |

| Sopras Tek 40lbs | Kevlar weave | ~$780 |

Incidentally the Sopras Tek is made from the strongest material – Kevlar, unfortunately there was scant information available from it and a concern that after-market support will be poor since it’s an uncommon brand, plus it was the most expensive of the line-up. CORDURA® Brand of Ballistic Fabric is as tough as it gets is an inter-woven yarn of nylon used to make military-grade clothing, gear and has various weave (denier) densities from 470 dTex all the way to 1680 dTex.

“Denier” refers to the weight, not the strength of an individual fibre that goes into making a fabric. Therefore, a higher denier count means a denser fabric. Strength and abrasion resistance are achieved via how the fabric is spun, or woven. These characteristics are measured through tenacity (strength per denier), breaking strength (tenacity x denier) and toughness. Cordura 1680 Denier is as tough as it gets and 1050 denier fabric meets U.S. Military Specification MIL-C-12369F-GL.

These nylon materials are sometimes known as “Rip-stop” from various manufacturers, and is used to make parachutes, gliders, tents, tarpaulins and climbing harnesses. They’re strong and don’t tear or rip easily. The Scubapro x-tek’s outer wing is made from 1680D Ballistic nylon outer shell and a 420D nylon inner bladder. I was able to get a great deal from Amazing Dive shop and ScubaPro being one of the biggest names in diving, spare parts for the inflator hose and dump valves would have been easy to procure. Scubapro X-Tek Donut Wing – 13KG Bladder (Single) bladder was thus selected.

Harness

Ok, now that the backplate and bladder is settled. I didn’t want to go around with a hard bare backplate, jumping into the water with twenty kilos of gear strapped onto it. After reviewing several backplate padding types, I decided on the xDeep 3D mesh as it was made out of a neutrally buoyant material – aramid. Aramid is a class of synthetic composites used in aerospace and military applications, for ballistic-rated body armour fabric and ballistic composites, they’re used to make fire-men’s uniforms for it’s fire-retardant properties.

Standard backplate padding’s foam material compresses at depth and might require additional weight to compensate. The softness results from springy fibres inserted in a special manner in the mesh structure. A secondary alternative I was considering was the hollis backpad combined with a 1000Denier Corduroy Molle shoulder strap, but that will just be two different manufacturers, more sources to order from, not to mention the Molle shoulder strap will take a longer time to dry.

According to xDeep – the design allows water to easily flow through the mesh, and the pressure does not have any impact on its parameters. Padding made of 3D Mesh does not compensate under pressure, is equally soft at all times and does not require additional weight. It also dries much faster than the classic foam.

Excellent, I got a set.

It is easier to link as many components as possible to one manufacturer/brand since shipping together reduces cost. xDeep’s webbing claimed to be made of polyamide, which is possibly simply nylon and totally resistant to water, so I got a roll and the accompanying stainless steel buckle, crotch strap, tri-glides and 316L stainless steel D-rings.

One thing I really wanted was a quick-release/adjustment system from the BCD in the event I need to release my BCD quickly to assist other divers (i.e. up a dinghy) and tested several systems. Whilst I liked the DiveRite clip system, the release buckles do present a potential weak-spot and point-of-failure. Should the plastic buckles break, overall system integrity is compromised, so the 2” webbing should retain full continuity for maximum strength.

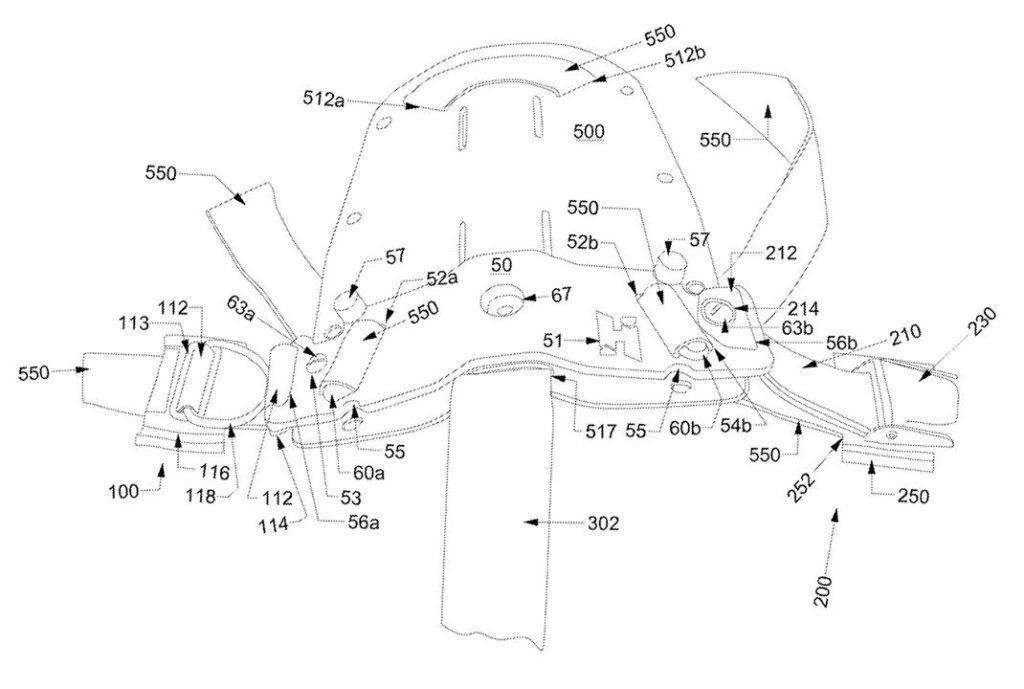

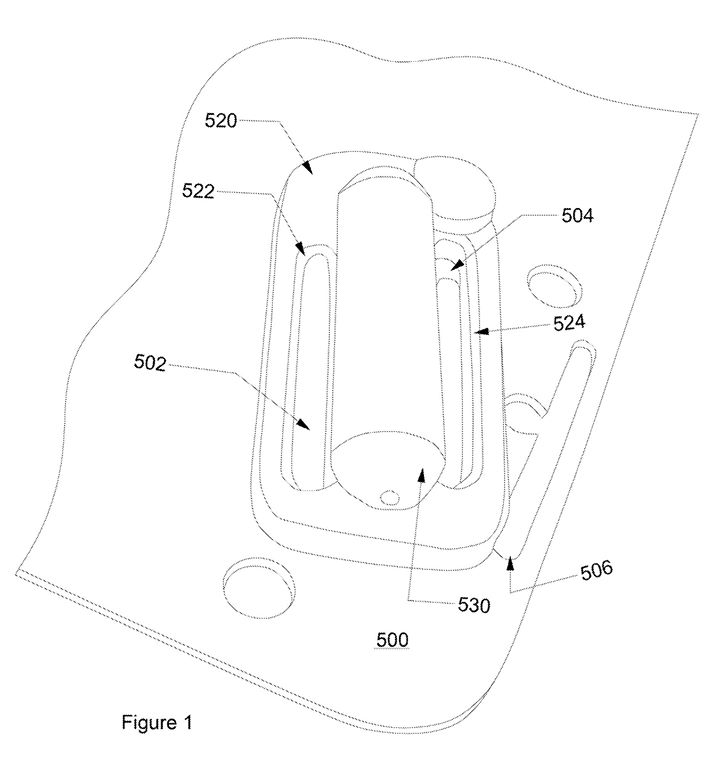

What I found for a quick-release/adjust system was a nifty little retainer/cinch. It basically acts like a figure-8 belay device used in climbing where there is tension in one direction and reduced tension in another direction. The Cinch Quick-Adjust Harness from Halcyon specially designed for this purpose and cost S$188 in Singapore.

You can read more about the retainer in Halcyon’s patent here, the retainer accessory permits a diver to quickly adjust a one-piece continuous piece of webbing by simply pushing or pulling the webbing in the desired direction which allows the webbing to slide on through the attached accessories without affecting the location of the accessories with respect to the diver’s body.

However, I think $188 is too expensive and instead cinch adapters like this are available, or you could make it yourself. I got myself two to test and they work rather well. So now I have a continuous webbing harness that is both strong and quickly adjustable any time prior to a dive or during a dive.

Weight Pockets and carabiners

Weight belts were definitely out of the question, it’s another piece of gear to worry about when you’ve a dozen other items that could get misplaced in the hustle and bustle of diving. Many manufacturers offer “release pockets” specific to their product design and are mainly centred at the waist, the idea is that in an emergency the weight pockets can be discarded.

Well. How often does that happen? Discarding weights for an emergency ascent is a bad idea and isn’t an option at 30 metres – it simply denotes poor dive-planning, so I decided my weight pockets will just primarily be compensating in the event I have to dive in a dry-suit or 7mm wet-suit.

Again, I found inspiration with Halcyon’s setup where the weights are placed as close to the body as possible on the backplate itself! Great for keeping the trim horizontal and keeping weights as close to the body as possible.

I got four affordable weight pockets from EZ-DIVE at $20+ each (although this could be another component that could be avoided for cost-savings) since it’s just a Velcro pocket. The weight pockets were designed to be slipped onto a weight belt, and to solve that, I sewed on some Velcro straps to the pockets so that it can be mounted horizontally onto my backplate.

The weights slip in from the top, and is neatly mounted onto the backplate and hidden by the bladder. Completely out of sight and unobtrusive.

Single Tank adapter and tank bands

The major components are all accounted for, Carbon fibre STAs are available but cost five times more with little gain in weight savings so I got an aluminium Single Tank Adapter (STA) with 2 Super Cinch Straps for $155. The super cinch tank bands are great!

They unclasp completely so you don’t have to slide the BCD over the tank, and instead I will be able to place the BCD flat on a boat deck and place a tank on the BCD or if the tank is in a tank-rack still being charged, I will be able to mount my BCD onto the tank without having to move the tank at all. Extremely convenient over existing tank bands.

Putting it all togetherIt’s time to assemble all the components.

It’s time to assemble all the components.

As for my SMB and reel and spare mask, they are are stored in a military-style bottle holder made from 600D Nylon which actually works out very well and are mounted on the waist-webbing and attached to the backplate via cable-ties. To reduce further weight, all non-load bearing carabineers are plastic and the submersible pressure gauge (SPG) is a nice glow-in-the-dark carabineer.

One unique feature I added is a quick-release mount for my dive-torch based on the military 26mm picatinny rail weapons mount. I decided it will be mounted on my right shoulder pad instead so that it won’t interfere with my inflator hose, and the knife will have to go to my waist webbing. With that, I now have a hands-free torch mount that I can remove and re-mount as and when I need it. It can be removed via a thumb-button with one hand.

The last feature I have is a military-grade type-III paracord, (a lightweight nylon kernmantle rope used in the suspension lines of parachutes) as handle that I’ve attached to two D-rings just aft of my bladder. This allows me to carry the BCD or hang the BCD up to dry on a hook in a more comfortable manner, plus it looks sleek and has a breaking strength of 550lbs (249kg), I won’t even be able to lift that much less worry about it breaking.

Testing and summary

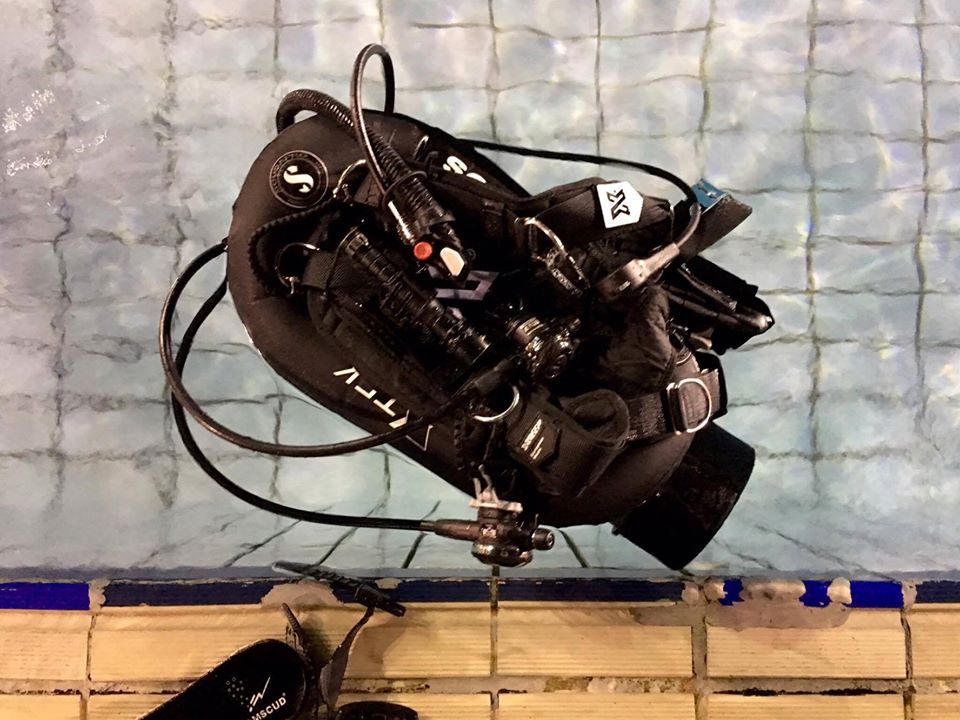

I took it out to the pool for a spin, and it worked fabulously well. (I have to admit I am somewhat biased towards my own work), even in non-saline pool water, no additional weights were needed, buoyancy and trim were great, the setup felt sturdy and the ScubaPro bladder works a charm.

Field testing

The total weight of my BCD setup is a scant 2.40kg and all in all, this project cost me about S$1.2k give or-take. As of today, I’ve done about 30 dives on this BCD and so far, really satisfied with its performance. The whole endeavour of this exercise is to keep the weight low, and with all accessories mounted or in the pouches (SMB/reel/hook/knife/torch/spare/etc.), the assembly weighs 4.8kg, thus allowing further weight allowances for other gear and devices. For lighter BCDs, you’ll have other options such as travel BCDs or skeleton BCDs, unfortunately they may not provide the same flexibility or versatility as a full-fledged backplate for technical applications.

If you’re still reading this article to this point, I would like to thank you for your interest and to the various instructors, friends and fellow divers who have helped in procurement of the various components and provided me with their opinions, advice and support.

Dive On.